Oh dear, I'm not having much success at stitching a design on a T-shirt. For some reason I've just never embroidered on a knit! I've ironed on a fusible stabilizer on the shirt, hooped no-show-mesh and then pinned the stabilized T-shirt on the mesh. The picture shows my first colour and it's already beginning to buckle. I read somewhere that you should never sew further than you are willing to pick out...so I stopped. This is not something for sale...just a top to go with pajama bottoms I made for my grandson. Sorry, the picture does not show what I'm trying to explain very well, but to the right of the needle there is a definite bump in the fabric. I think I'll get out my stitch ripper and do some "reverse" sewing while I wait for any help and suggestions. Thank goodness the stitches are quite long! Avis

Like several others have already pointed out, what I find works for me is to hoop poly-mesh underneath and then use a topper - I usually use WSS. I took a class once that suggested sticky WSS on the back and WSS on top. I found that the sticky WSS had a tendency to stretch the t-shirt even though I tried not to. Anyway you will find what works for you. Good luck.

1 comment

Thank you for your idea. Something will work out...I know, I've had so much help. Blessings, Avis

one solution to save the t shirt without unpicking is to applique something over the existing embroidery or do the design as a badge and sew it on

1 comment

Lovely idea, though it's all picked out and ready for me to get with the programme!! I appreciate your input. Be blessed, Avis

I have stitched hundreds of T shirt designs. I don't ever hoop a T-shirt or a towel. I use Sticky stabilizer on the back and stick the shirt on that, smoothing out any wrinkles. The stabilizer I use (Sulky Sticky) is plenty sticky, and it also will allow replacement if I need it. Then, I also use the clear WSS on the top, so the stitches won't sink in to the fabric. In this photo I used an iron on, and you can definitely see how it shows the shape behind it. Do Not consider this as an example of good hooping.

1 comment

Thanks for your input. This project is on the back burner for now as our family has been down with the flu and colds and the s/m is low priority. Once I get this stitched out I will post it so that you all will know that your contributions have been heeded. Be blessed this Christmas season, Avis

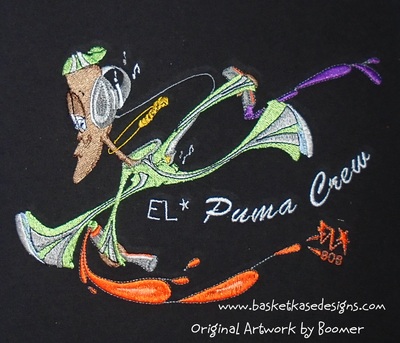

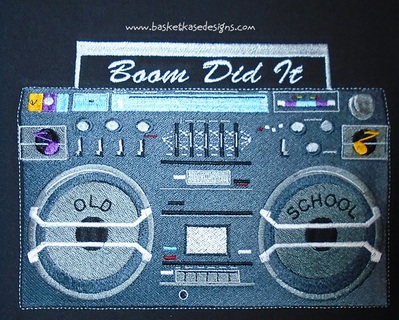

Hi Avis......I have done tons of tshirts especially for Boomer and his designs are always 50,000 to 75,000 stitches.....I hoop 3.0 oz cutaway with the tshirt and they stitch beautifully......below are some examples...

3 comments

You rock! Those stitchouts are lovely. I am so on an upward learning curve through all of this and really appreciate your comments along with everyone else's. Blessings, Avis

by basketkase

10 Dec 2017

by basketkase

10 Dec 2017

Avis......I have been where you are and believe me, as you are finding out this website is the best!! Everyone here is so knowledgeable and excited about sharing what they know........good luck and many blessings to you......

I think what you do is specific to each machine. One machine will do fine with a techinque that does not help on another machine even if it is the same brand. So, it would be wise to practice on some old tshirts to see what teniques work best for you. What works on my Bernina does not work on my Babylock as well.

Finally, all tshirts are not the same quality. Seems like the thin tshirts are dominate now and I prefer a heavier weight tshirt and have to shop around to find one!

I like a soft feel to my tshirts, so I put two layers of iron-on mesh on the back with the second layer ironed on in the opposite direction of the first. On top, I put two layers of washaway. For the first layer of wws I just use scraps that overlay each other a small bit, but a whole sheet on the top of the scraps to hold them down. Otherwise your foot could get caught in the scraps which is a real problem. I find that putting some wss on top seems to add a tiny space so the thread tension is a little looser which helps reduce puckering. I do not use spray glue, just lay them on there. I usually do a basting box to hold everything down.

Sweatshirts are done differently, so you may need to practice on those too.

Please consider using WSS on top instead of iron on as, by ironing stabiliser onto the fabric, it becomes part of the fabric instead of stabilising it.

You can SLIGHTLY stretch the fabric but beware not to stretch it too much, rely on the HOOPED WSS on top to keep the fabric from buckling or bunching.

I would definitely test stitch the design onto an old t-shirt using this method before stitching it onto your garment. Good luck with it.

hugs n roses, Meganne

5 comments

I knew this was the right place to ask my question! Thank you for the wss tip. So...do you just hoop the knit and wss as one piece in the hoop? Do you put anything behind the fabric? I won't have time to work on this until tomorrow so I'm asking all my questions now. Blessings, Avis

by basketkase

10 Dec 2017

by basketkase

10 Dec 2017

Great idea, Meg........I will try this as well and use no show mesh on the back next time I do a tshirt for Boom......his are always 50,000-75,000 stitches as he need so much detail shown in his work.......I also do not run my machine at full bore, I slow it down and that sure helps....

I don't think I have ever run my machine at full speed; usually 1/2 speed for embroidery and depending on the density, a little slower yet!

by meganne

11 Dec 2017

by meganne

11 Dec 2017

Hi Avis, I usually use 'No show', or WSS, or cutaway underneath.

A lot of factors come into play before I decide which one I will use... thickness of fabric, amount of stretch, one way or two way stretch, type of embroidery design, density of embroidery design, if it has good underlay or NO underlay?

But I always use Fabric type WSS on top as, besides stabilising the fabric, it helps keep the stitches ON TOP of the fabric, instead of them sinking into it, this is especially useful when stitching text.

Over time, and with practice, you will come to instinctively know all the things to look for, that will help you decide how you will proceed. For me I ALWAYS, test stitch EVERY design on fabric as close to the garment as possible, as it helps me decide the best way to get the best result.

with stretch fabrics, if I know it is not going to be stretched tight on the wearer, I will hoop with as little stretching to the fabric as possible, even if it means measuring the design and putting pins in the fabric to show exactly how big it is, so that when I hoop it, I measure the pinned area again to make sure the fabric has not been stretched.

I have a stretch top I wear that I had to stretch out, a lot, when I embroidered it, so that so that it would look good when I wear it, but if you saw it not being worn it looks all wrinkled and puckered. :-)

Sometimes I hoop all three layers: underlying stabiliser, fabric and top stabiliser,

other times I will only hoop the bottom two and pin the top stabiliser in place, pulled tightly, taking care not to pull the fabric.

Yep, I'm really pedantic when I embroider things, and all of these hints are just little things to jot down and think about depending on how fussy you are with your embroidery, so I hope some of it helps.

Hey Vicki, I also have never run my machine at high speeds, I'd rather do a good job than a rush job. :-)

And I prefer Fabric type WSS over that horrible plastic. :)

Hugs n roses, M

I think I'm going to have to print this whole lesson out...everyone has given me such sensible information and I will work on a test stitch out today. My design is not dense, it sort of looks like a pencil sketch so that is probably a good one to start on. Since I discovered the Fabric wss I have never gone back to the plastic...I buy mine by the meter when it goes on 50% sale at Fabricland...usually buy 10 meters at a time as I don't live near the store. My hubby is out of town today so it's me and my sewing machine and no interruptions!! Yeah!!! Avis

Can't wait to hear how this turns out. Hope you are successful.

1 comment

Sewmum1 has given you some great suggestions. If you need to see further information try YouTube on how to sew on T-shirt fabrics. There are videos on everything these days. I knew T-shirt fabric tends to be quite stretchy, but from what you've said you sound like you've got most bases covered. Is the design purely a machine embroidered design and not an FSL (free standing lace design) that you are trying to sew out? Love Chris

1 comment

Thanks, Chris. I do watch a lot of YouTube. I live in a very small community and there aren't many opportunities to take classes so I bring the teachers into my living room!! This design is from JBLON. I've stitched others but always on woven fabrics.

I know there will be other suggestions but a few things to check when this happens to me.

Make sure the thread from the spool is not caught on anything or knocked over

Use a ball point needle

Check the bobbin. One of my machines does not like stitching some designs with a bobbin less than half full and will behave like this. I also have a black spool if thread if used in the bobbin will misbehave too

Check for thread nests. My last embroidery had a very difficult to find thread nest under the bobbin casing that pulled some fabric into the needle plate after puckering a design I knew was good to stitch

Sounds like it is well stabilised and you also have pins and basting stitches in but depending on the quality of the knit tshirt I sometimes use 2 layers of cutaway mesh with the grain sitting opposite directions

Some designs will stitch out better on knit with water soluble stabiliser on the top.

Hope these help for now so you can get back to embroidering

3 comments

Thanks so much for so many things to look for.

I had just cleaned the bobbin area and put in a new ball point needle. The bobbin was freshly filled as this was a new project so there wasn't a problem there.

I've taken the T-shirt out of the hoop and there were no nests anywhere and I'm in the process of doing my reverse stitching!

The tension looks great both top and bottom so both threads are feeding correctly. It just seems that as it stitches the fabric is being stretched and eventually ends with a bubble.

I think I'll try this on a sample piece of fabric and use a heavier iron-on stabilizer directly on the shirt before I place it in the hoop. I recently bought a sticky wash-away so maybe that could prevent the shifting.

I'll try again tomorrow and will post what happens: it will either be a success or try again!

Thanks again and be blessed, Avis

some designs are very stitch intensive and just dont work well on knits- I find the best designs for knits have a universal underlay which sews out over the whole design- not bit by bit- even though I have done a lot of machine embroidery I got caught the other day by a design that is often referred to a bullet proof I had 2 layers of woven iron on stabilizer and it still buckled-didnt heed my own advise

Thanks for sharing that...even the "DO NOT DO" things are helpful. I appreciate your taking the time to explain this. Be blessed. Avis