A new post of hints and tips concerning embroidery would be a good idea right now. I will start.

Never spray canned air into your embroidery machine. It will force the bits of dust and thread into the inner workings of your machine. It can remove/displace the lubricants used to keep your machine running smooth. Instead, use the tiny vacuum attachments made for computers to carefully suck out all the fuzzy mess.Please add your tips to this post instead of creating a new post. That way they will all be in one place

Once again I 'Thank you' for these tips, as they have given me much new information to help on my journey as an embroider.

1 comment

use one of the tiny tooth brushes that look like minature bottle brushes to clear thread stuck between the tension discs and to clear fluff from those akward places

Fantastic idea rescuer, My tip for dealing with Big reels on Little machines, use an old CD on the spool. :) PS Never keep your spray glue by your hair spray...Trust me I know ;)

2 comments

Catch and save all those little tails of embroidery thread. I use a little enamelled bucket but a small fabric 'box' will do just as well. Those threads add up and one day you'll be able to make a pretty motif, collar, pocket top, whatever, by sandwiching them between tulle or by sticking them onto sticky stabilizer and stitching them to create a new fabric.

AlmaG.

2 comments

by rescuer

06 Apr 2014

by rescuer

06 Apr 2014

I use an empty square tissue box (the kind with plastic on the top for single tissue delivery) to collect my threads. That way I am sure they will not get tangled in my embroidery machine (or my vacuum) at all.

Some of the threads seem to cling to everything!

Keep magnetic gadgets away from your machine. Computers and magnets don't like each other, so I'm told. Whatever anyone says, why take the chance when moving magnetic things a few more inches away will avoid having your machine play up.

AlmaG.

5 comments

by rescuer

31 Mar 2014

by rescuer

31 Mar 2014

This is so very true! Computers and magnets do not mix. Since embroidery machines have computers inside -- keep magnets far away from them.

by killiecrankie

04 Apr 2014

by killiecrankie

04 Apr 2014

I'm sure that I have seen lights that attach to sewing machines which use magnets.Always thought that they could cause modern machines loads of trouble

by katydid

05 Apr 2014

by katydid

05 Apr 2014

Wow !! Now i wonder about the magnetic hoops. Has anyone heard of them causing problems? Kay

by rescuer

06 Apr 2014

by rescuer

06 Apr 2014

I wondered the same thing. I would hope they are far enough away from the computer parts or aimed in such a way that they may not be an issue...but I have repaired computers that were "acting weird" by removing the many magnetic business cards from the side of the computer. The trouble is I could not replace the data they had lost as well.

Realize -- computer techs use magnets to wipe (remove nearly all) data from a hard-drive.

It does make me wonder if one could lose parts of the data for a design using them.

by basketkase

06 Apr 2014

by basketkase

06 Apr 2014

I'll weigh in on the magnetic hoops.....I do keep them away from my computer, but I have 3 of them and the gal who sold me the machine and spent a day training me made it clear to me that it would not harm the machine....

however when I snip jump stitches while the hoop is still in the machine, my scissors stick to the hoop...LOL!

Using a non metallic pipe cleaner instead of a brush to get all the lint. A lot more hangs up in the hair of the cleaner then in a brush.

Never pull the fabric tight after you have it in the hoop. You will distort the fabric leaving a misshapen mess of a design -- once the fabric is removed from the hoop -- especially after it is washed.

Remember to Press not Iron your fabric before you hoop. If you iron it you may distort the fabric and then when it is washed it will be misshapen.

3 comments

by gerryb

31 Mar 2014

by gerryb

31 Mar 2014

I'm not rescuer, but I THINK when you iron, you are moving the iron back & forth on the fabric. When you press, you are putting the iron down, then lifting it up without moving it around the fabric.

by rescuer

31 Mar 2014

by rescuer

31 Mar 2014

Gerry has it right. Sorry, I should have made that clear. Thanks Gerry for helping me out.

My hint is when filing a design on your computer, don't just put that design in a file such as "flowers" or "In the Hoop", but also file the design by the designer's name (or website name). For me, it makes it easier to find the design I need and also, to check on the licensing of designs if your are incline to sell a stitched out design. Hope that makes sense!!!!!

2 comments

by katydid

05 Apr 2014

by katydid

05 Apr 2014

Yes , for the first few years I did file by category and I do still use a lot today, but I started filing by web site as as it is easier to locate a sites designs. Within each folder I keep purchased designs separately from freebies, making them easier to locate.about 5 yrs ago I started a folder eg "Ready to Machine 2014". one could even break it down into months if you wanted too. This has been my life saver. I park designs here that are ready to stitch and so easy to go to this folder and find projects that I spent time on fine tuning and send them to my machine. Kay

Here's a trick to re-hoop properly when your hoop pops loose, or gets bumped. 1) Hoop a piece of tear away stabilizer and go to the outline color. 2) Stitch the outline only on the stabilizer. 3) Lay the stabilizer over your embroidery to get it perfectly aligned. 4) Pin it well. 5) Re-hoop your project along with your embroidery blank and the outline stitched on the tear away. 6)Remove the tear away stabilizer that you used to line it back up with by tearing it away from your design area. 7) Start back stitching where you left off.

7 comments

Thanks for the tips that are here already and maybe you need a folder to stick these in for the rest of us. Thank you again.

I just happened to use a fabric that I'd placed fusible interfacing on for another project and because it was cotton it worked on my stitch out. Has anyone else tried this?

1 comment

by rescuer

06 Apr 2014

by rescuer

06 Apr 2014

I have used interfacing for light designs before. It works well on some projects.

Templates, I always print out a template for placement. If it is for a shirt, I lay it where I want it, mark lines and match those up with the lines on the hoop. I

make sure I have all the threads out that I'm going to use on the project. Hugs..Carol

4 comments

Thank you for this tip, never thought of doing this and it helps with my learning something new today. :)

by katydid

05 Apr 2014

by katydid

05 Apr 2014

Yes, I always print out template and thread color change and lay it next to machine as I stitch. Especially handy when you must stop in the middle of a design and you can mark your place on the paper. Kay

Sometimes I want to remove a commercial embroidery from a garment for replacing the design with something new. This is an easy way to do it: hoop the embroidered part with stabilizer and put it upside down on a flat object (a box or tin can, etc.). Use a disposable razor and shave off the backside of the embroidery very carefully, just down to the stabilizer. Now when you turn the hoop you can easily rip off the thread on the upper side. If you choose the new embroidery design a little larger, the erased area is completely covered and invisible.

6 comments

by eggyannie

04 Apr 2014

by eggyannie

04 Apr 2014

you can also us a piece of fine sandpaper to get rid of the unwanted stitches, good if there are just a few left that need to be loosened up

Can you use a regular vacuum cleaner to suck the lint out? Or is that too harsh? My serger gets sooooo bad!

5 comments

by rescuer

30 Mar 2014

by rescuer

30 Mar 2014

Yes, just find an attachment (made for computers) that makes the opening really small. Office stores and even Walmart carry the attachments. They work well. Just be sure to remove anything small enough to be sucked up by the vacuum.

by gerryb

30 Mar 2014

by gerryb

30 Mar 2014

Tks. My son gave me a hand vacuum with that attachment that was supposed to fit...of course it didn't. BUT did fit my canaster vac. Lots harder to get out, but will use it!

You can cover the nozzle of a vacuum attachment with a piece of old pantyhose and secure it with a rubber band if you afraid of sucking up something small. Works for retrieving small parts too, like a dropped screw or broken needle, they will be laying on the pantyhose until you turn off the suction.

Thanks for that one, I generally try to use a magnet that I glued to the end of a chopstick for anything metal

Make sure you starch your fabric (unless it is something like fleece or velvet). It is so much easier to handle. And be sure you have all the items you need to finish your project before you start it.

Air you say??? My machine man used his compressor to blow out all the dust you just blow from right to the left so it won't go towards the eclectic parts ,i do this about once a week .hugsCarolyn

6 comments

by rescuer

30 Mar 2014

by rescuer

30 Mar 2014

My repairman also has a compressor. He showed me what happens when the machine is not "opened" and the canned air goes into the gears and belts and I watched the lubricant move away....

I know you are brave and far away from shops -- but be careful dear Carolyn.

I wouldn't have said a word........................I've only got one head!!

Centering a towel, hankie, etc. for hooping. Fold in half and in half again. Place "point" on the cross hairs of your hoop (center). Unfold and unfold, place other part of hoop on and you're ready. Be sure to use WSS if towel has pile/depth so our stitches will stay on top.

My tip read all the tips here, you will learn a lot

3 comments

This is an excellent idea for a thread, but I'm afraid my mind is a blank! Perhaps I'll think of something to add in the morning.

2 comments

Sue you contribute here in many ways particularly in creating great designs for us to sew out

one more tip always schedule regular maintenance on your sewing machine at least once a month clean it out & oil in the right spots, most manuals tell you how to do this & if you use fleece or flannel or fuzzy type fabrics you should do it more often.

2 comments

by mops

31 Mar 2014

by mops

31 Mar 2014

I clean the bobbib area every time I have to change a bobbin as it is open anyway.

by killiecrankie

04 Apr 2014

by killiecrankie

04 Apr 2014

Neither my overlocker or sewing machines use oil, yet husband often asks me for machine oil .I found some amongst his stuff in a cupboard in the garage last week

My tip for all the fsl that gets done here. Never dump the rinse out into your drains this is after all GLUE & it will gum up your pipes. I have noticed that I dump my residue onto my garden rocks & they are very shiny, so don't put the water residue in a spot where you want something to grow because it is GLUE & it will not grow lol ~hugs~

1 comment

by katydid

05 Apr 2014

by katydid

05 Apr 2014

I have dumped mine over the back deck for years, since we talked about it. Plumbers cost to much to call out. Kay

My tip is, that as someone who is not too tidy when they are sewing is that I have tied with a long ribbon the small screwdriver and the thingy that is important when rethreading my big machine. (So far its working fine as they are always there and they are not lost)

3 comments

There's one or two here that may benefit from doing this with their scissors by all accounts!

Dennis I would never get near my machine if I hung all my scissors from it. Instead I keep my scissors hanging from a mug stand

I'm the metallic queen! LOL

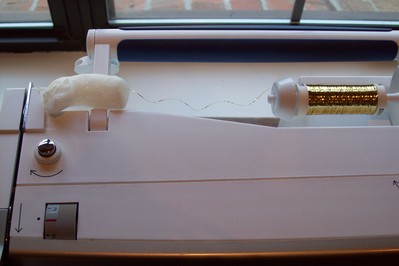

Stitching with metallics: my dealer told me to put the metallic on the regular thread stand (horizontal) then thread a sewing needle with the metallic thread. Sew directly through the center of a packing peanut and take off the sewing needle. Finish threading my machine leaving the packing peanut at the initial point of entry to the threading process and voila! I don't even slow my speed down but about 10% and it doesn't twist or break.

10 comments

Now that is good did not understand when I first read your tip so glad there was a picture to help I NEED visuals

by gerryb

30 Mar 2014

by gerryb

30 Mar 2014

Wonder if the packing places will think I'm crazy if I go in & ask for ONE packing peanut?? Rarely get those anymore in packages...it's usually that blown up bags.

Great idea, thank you! I am stitching with metallics very often, and though I use a VERY long thread stand distance to my machine the thread is frequently breaking ... I will try it next time :)

Those plastic pillow bags that are used for shipping are good to stuff in purses being stored on a shelf or rack in the closet. Keeps them from drooping, collapsing and disappearing in the crowd.

What's a 'packing peanut' when it's at home? My garden squirrels eat peanuts!

A packing peanut Dennis is what the small white bits of polystyrene that are used in packing a large container usually a new machine, whatever to protect it as it leaves the factory.